Add to Cart

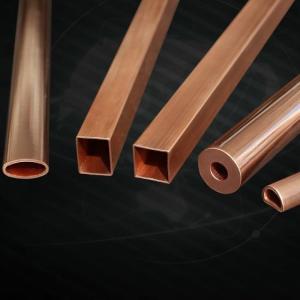

Copper-Nickel Pipe (also known as Copper-Nickel Tubing, Copper-Nickel Pipelines, or Copper-Nickel Tubes) is an excellent choice for use in a variety of applications due to its high yield strength, high tensile strength, good weldability, and superior corrosion resistance. This material is ideal for use in highly corrosive environments, where its superior corrosion resistance can help extend the life of your piping system. It is also well suited for use in applications where temperature extremes are present, as it has a wide range of temperature tolerance. Copper-Nickel Pipe is commonly used in chemical processing, power generation, marine applications, and much more.

The combination of copper and nickel in Copper-Nickel Pipe makes it an excellent choice for many applications. Copper provides great strength, while nickel adds excellent corrosion resistance. This makes Copper-Nickel Pipe ideal for use in high-pressure and temperature-sensitive applications, such as those found in chemical processing and power generation. Copper-Nickel Pipe is also ideal for use in marine applications, as its superior corrosion resistance makes it perfect for use in saltwater environments.

Due to its superior weldability, Copper-Nickel Pipe can be easily welded to create complex piping systems. This makes it an ideal material for use in many industrial applications, from chemical processing to power generation, and from marine applications to water treatment. Its superior strength and corrosion resistance make it an excellent choice for use in many applications.

At its core, Copper-Nickel Pipe is an excellent choice for many applications due to its superior strength, corrosion resistance, and weldability. Its superior corrosion resistance makes it perfect for use in highly corrosive environments, while its good weldability allows for complex piping systems to be easily created. Its high yield strength and tensile strength make it an ideal choice for use in a variety of applications, from chemical processing to power generation, and from marine applications to water treatment.

| Attribute | Value |

|---|---|

| Heat Treatability | Good |

| Material | Copper Nickel |

| Size | Customized |

| Formability | Good |

| Tensile Strength | High |

| Machinability | Good |

| Yield Strength | High |

| Length | Long Length |

| Weldability | Good |

| Corrosion Resistance | High |

Copper-Nickel Piping is an ideal product for a wide range of industrial and commercial applications. It has excellent machinability, weldability, heat treatability and formability. It is highly corrosion resistant and has superior formability. The brand name is Metal, and the model number is Nickel Pipe. It is certified with ANSI B16.9/DIN/JIS. The minimum order quantity is 1, and the price is 9. It is packaged in standard shipping package and delivered within 15 workdays. The payment terms are T/T, L/C, and Western Union. The supply ability is 100tons/month. It has good machinability, heat treatability, weldability, corrosion resistance and formability.

Metal offers high-quality copper-nickel piping products, certified according to ANSI B16.9/DIN/JIS standard. Our Copper-Nickel Piping is of good machinability and high corrosion resistance. You can order customized copper-nickel piping with a minimum order of 1. The delivery time is 15 workdays. Our price is 9 and the packaging is standard shipping package. We have a supply ability of 100tons/month. We accept payment terms of T/T, L/C, Western Union. The length and size can be customized.

We provide comprehensive technical support and services for Copper Nickel Pipe products, which includes:

Our experienced team of engineers is dedicated to providing you with the highest quality technical support and services to ensure that you get the most out of your Copper Nickel Pipe products.

Copper Nickel Pipe Packaging and Shipping:

Copper Nickel Pipe is packaged in wooden boxes with an inner lining of plastic film to protect the material from moisture and corrosion. Each box typically contains 20-25 pieces of pipe. The boxes are then placed on pallets to facilitate safe and easy transport. The pallets are then wrapped in plastic film and shrink-wrapped for added protection. The pallets are then loaded onto trucks or other transportation vehicles for delivery to the customer.